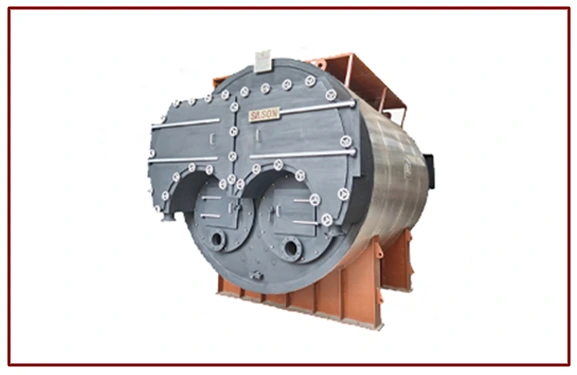

Twin Furnace Boiler Manufacturers in India

Twin Furnace Boiler Suppliers in India

SILSON Boilers is one of the leading Twin Furnace Boiler Manufacturers and Suppliers in India. Our sector-specific industrial boiler solutions provide excellent performance standards paired with durable characteristics to fulfill customer satisfaction. Our boiler production includes customized solutions with tried-and-tested standards that provide high operational potential with consistent implementation throughout all our supplied components. We exist to manufacture durable boiler systems as Twin Furnace Boilers Manufacturers in India. The product unit makes use of modern technologies to reach both efficient energy consumption levels and affordable operations.

About the Twin Furnace Boilers

Two independent combustion chambers or furnaces found in twin furnace boilers enable both increased capacity as well as better efficiency performance.Such boilers serve industries that need substantial steam production. Such boilers carry two combustion chambers or furnaces which grants better steam production capacity while enabling users to select different fuel types. We operate as a major Twin Furnace Boilers Suppliers in India to serve customers with diverse requirements. We deliver customer support alongside thorough after-sales service as well as supply alongside installation for seamless operations. The application of these boilers suits the requirements for industrial processes that need both high levels of heat and pressure.

Types of Twin Furnace Boilers

The Twin Furnace Boiler Manufacturers in India present an extensive range of high-grade boilers that are flexible enough to be applied in all types as follows:

- Twin Furnace Fire Tube Boiler: A twin furnace fire tube boiler reaches superior efficiency through its dual furnace construction that enhances heat transfer capacity. The steam and hot water production system consists of fire tubes that transport hot gases within water to fulfill multiple application needs. The system design enables minimized energy usage alongside an extended operational period through its optimized combustion together with heat exchange processes.

- Twin Furnace Packaged Boiler: This packaged boiler system contains two furnaces that can be installed easily after assembly in a factory facility. This system delivers outstanding performance while maintaining compact dimensions because production managers typically apply it to generate hot water and steam for industries that demand substantial quantities. This boiler design comes pre-assembled which shortens installation duration and decreases expenses because its dual furnace arrangement enables more dependable operation combined with improved load handling.

Specifications of Twin Furnace Boilers

We have added below a technical sheet of our Twin Furnace Boilers that provides more technical information such as:

| Specifications | Description |

|---|---|

| Boiler Type | Twin Furnace Boiler |

| Capacity | 10,000 kg/hr to 200,000 kg/hr |

| Design Pressure | 10 bar to 150 bar |

| Fuel Type | Natural Gas, Oil, Coal, Biomass, or other specialized fuels |

| Efficiency | 85% to 95% |

| Heat Recovery | Optional economizers, super-heaters, air preheaters, and heat exchangers for improved energy recovery |

| Boiler Type | Water-tube or Fire-tube designs; typically water-tube for high-pressure boilers |

| Furnace Design | Dual furnace configuration for improved combustion and heat distribution, typically with separate burners for each furnace |

| Water Wall Construction | Membrane-type water walls |

| Boiler Material | Carbon Steel, Stainless Steel, Alloy Steel for improved strength and corrosion resistance |

| Burner Type | Multi-fuel burners, designed for efficient combustion with low emissions |

| Steam Quality | Saturated or Superheated Steam |

| Blow-down | 3-5% |

Benefits of Twin Furnace Boilers

Being Innovative in the category of Twin Furnace Boiler Suppliers in India, all types of boilers are made using advanced technology and hence offer a variety of benefits such as:

- Enhanced Efficiency: The continuous operation of these boilers alongside one another achieves optimal performance levels while minimizing power usage for stable temperature output. The dual heating system decreases energy spending while preventing resource losses.

- Improved Redundancy: Dermal heating is provided by dual furnaces as a backup system that suits applications requiring dependable heat throughout large properties and residential structures. A backup system equipped in these setups ensures heating machinery remains active during severe weather conditions.

- Extended Lifespan: When each boiler unit works together to share labor duties twin furnace boilers operate with reduced wear and leave a longer operational time. Maintenance routines extend the operational span of the system.

- Better Heat Distribution: Such setups unite two furnaces to create even heat distribution across large areas thus improving comfort levels in homes and buildings. Both rooms receive heating from these boilers which maintain identical thermal levels.

- Cost Savings in the Long Run: Because these boilers require increased installation expenses at first they deliver major energy savings and prolonged durability which generates long-term financial advantages.

Applications of Twin Furnace Boilers

As Twin Furnace Boiler Manufacturers and Suppliers in India, our boilers are highly demanded for multiple types of applications and used for improving performance, such as:

- Large Residential Homes: These boilers work best for big homes containing different levels because they deliver steady heating throughout all spaces including demanding areas.

- Commercial Buildings: These boilers maintain efficient heating performance in offices as well as schools and hotels because they deliver needed comfort levels throughout building spaces.

- Industrial Facilities: The high heat requirement of industrial production can be satisfied by twin furnace boilers due to their strong capacity alongside their energy-efficient design which reduces operational interruptions.

- District Heating Systems: These boilers serve district heating systems perfectly since they transmit heat through central networks to various buildings in residential areas while providing reliable energy efficiency.

- Hospitals and Healthcare Facilities: Hospitals rely on twin furnace boilers for critical heating requirements because they provide effective and backup functionality to deliver safe operational temperatures for patients while protecting staff.

SILSON is the Twin Furnace Boiler manufacturers and suppliers in India while serving the industrial steam requirement needs of demanding sectors. The product design delivers superior combustion efficiency with fewer emissions while delivering better performance results. Our commitment to quality combined with customer satisfaction makes us a dependable entity within the boiler market. Connect us now to acquire Twin Furnace Boiler systems at the highest level.

FAQ

Ans: A two-stage furnace offers two levels of heating power. It can provide more efficiency and even warmth in your home.

Ans: A dual fuel system may come in the form of a packaged unit or a split system with two energy sources: the electric heat pump and a gas furnace. Dual fuel technology combines the cooling and heating performance that you get from a heat pump with the consistent heating capacity of a gas furnace.