Top Steam Boiler Manufacturers & Suppliers in Pune | SILSON Boilers

SILSON Boilers is the prominent Steam Boiler Manufacturers in Pune, We are also leading Steam Boiler Suppliers & Exporters in Pune. Through our extensive experience, we dedicate ourselves to manufacturing durable steam boilers that meet the industrial requirements of power generation manufacturing and chemical manufacturing.

SILSON Boilers – Trusted Industrial Steam Boiler Experts Since 1989

We operate as a leading Steam Boiler Manufacturers in Pune that produces boilers specifically to meet customer needs along with enhanced operational performance but lower expenses. We design integrated with advanced technology to create reliable and safe operational conditions for both small-scale and large-scale applications.

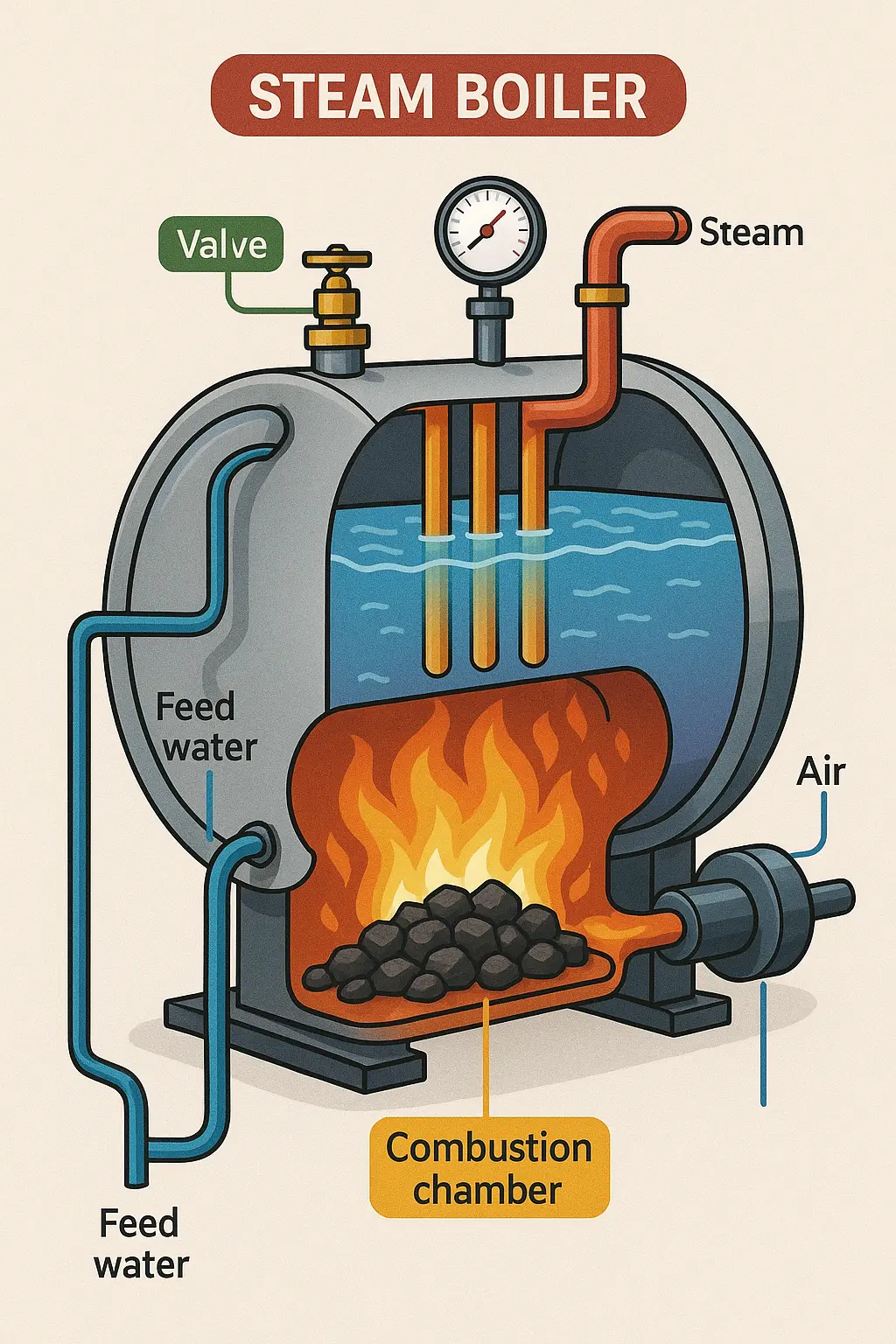

About the Steam Boilers

The purpose of steam boilers is to heat water into steam which supports numerous industrial operations. The production of heat and power in industries that include food processing chemical production and power generation depends on these devices. Fuel conversion produces heat which steams water into high-temperature vapor during operation. As the Steam Boilers Suppliers in Pune, we support our customers through immediate delivery service and continuous support assistance. A customer-oriented operation drives us to produce and distribute high-quality steam boilers to businesses throughout the country.

Types of Steam Boilers

The Steam Boiler Manufacturers in Pune present an extensive range of high-grade boilers that are flexible enough to be applied in all types as follows:

- Firetube Boilers: The hot combustion gases flow through tubes that rest within a water-filled chamber in these boilers. These boilers work in low-pressure steam conditions because they operate through basic design principles which produce small and straightforward equipment. Due to their compact dimensions, these systems provide easier maintenance requirements and installation schedules. Their design and efficiency capabilities provide cost benefits to operations with lower steam demands and smaller operations.

- Water Tube Boilers: The furnace heats gas which passes through tubes carrying water in these boiler designs. Water tube boilers enable high-pressure and temperature steam generation which makes these boilers appropriate for big factory operations. These boilers offer superior performance under high-capacity and high-pressure steam operations which makes them suitable for commercial applications. The design achieves improved heat transfer performance together with rapid reaction times when responding to load fluctuations.

Specifications of Steam Boilers

We have provided a technical sheet of our Steam Boilers below. This sheet contains detailed technical information and specifications. It outlines the performance parameters and operational details. You’ll find data related to capacity, pressure, fuel type, and efficiency. Reviewing this sheet will help you better understand our product offering.

| Specifications | Description |

|---|---|

| Capacity | 500 kg/hr to 100,000 kg/hr |

| Design Pressure | 10 bar to 200 bar |

| Operating Pressure | Typically 10 bar to 100 bar, can go higher for specific applications |

| Efficiency | 80% to 98% |

| Furnace Type | Horizontal, Vertical, or Cyclone Furnace |

| Boiler Material | Carbon Steel, Stainless Steel, Alloy Steel, Cast Iron |

| Steam Quality | Saturated Steam, Superheated Steam, or Wet Steam |

Benefits of Steam Boilers

Being one of the topmost in the category of Steam Boiler Suppliers in Pune, all types of boilers are made using advanced technology and hence offer a variety of benefits such as:

- Environmental Benefits: This boiler technology features emission-reducing features that maintain business compliance with environmental standards. The efficient operation of steam boilers decreases the fuel needed which results in reduced carbon emissions during operation.

- Reliability and Durability: These boilers possess exceptional longevity because they sustain dependable operation in prolonged operation. Strong build quality combined with high-pressure capacity allows these devices to excel in intense industrial uses.

- Energy Efficiency: The process of water-to-steam conversion in these boilers enables high energy efficiency which minimizes waste. The heating system delivers continuous heat to industrial facilities and commercial buildings thus maximizing energy conservation.

- Versatility: These boilers operate across many applications which include heating production systems and power generation then industrial process requirements. The systems can be applied across manufacturing sectors along with food production facilities combined with Heating Ventilation Air Conditioning needs.

- Cost Savings: These boilers deliver maximum operational cost-effectiveness and durability which leads to substantial savings. Maintenance practices extend boiler lifespan which leads to cost savings over time.

Applications of Steam Boilers

We are renowned as a Steam Boiler Manufacturers in Pune, our boilers are highly demanded for multiple types of applications and used for improving performance, such as:

- Heating Systems: These boilers operate as a heating solution in district heating networks together with massive buildings. The heating operation of buildings and hospitals as well as schools and office spaces can be achieved through steam distribution from these boilers.

- Food and Beverage Industry: The food industry depends heavily on these boilers because they execute vital procedures including cooking sterilization and pasteurization tasks. The energy-efficient heating system uses clean procedures to meet temperature requirements for food production.

- Power Generation: Power plants require steam boilers as their fundamental element for electricity production. The steam produced by water conversion serves as the primary driving force to operate turbines that power generators at thermoelectric power stations.

- Industrial Manufacturing: The major applications of these boilers include textile production and food processing as well as chemical production activities. These boilers supply the required thermal energy as well as steam needed for medical sterilization operations and drying processes alongside chemical reactions.

- Healthcare and Hospitals: The healthcare sector employs steam boilers for performing sterilization as well as autoclaving their equipment. High-temperature clean steam generated by these boilers supports medical tool sterilization as well as ensures hospital hygiene standards and assists with multiple hospital operations.

SILSON Boilers, a leading steam boiler manufacturers in Pune, steam boiler suppliers in Pune, offers top-quality, efficient, and reliable solutions for diverse industries. We have accumulated extensive experience in developing performance-driven products that match client requirements. Our dedication to innovation as well as customer satisfaction establishes us as a dependable authority in the steam boiler marketplace. For the best steam boiler solutions, contact us today!

FAQ

Ans: A steam boiler is a system that uses heat to convert water into steam, which can then be used for various applications.

Ans: A steam boiler is a steam-producing heating system; it produces energy by heating water to create steam.

Ans: The classification of boilers is based on several factors and is classified into six categories: According to the contents of the tubes, the number of tubes, the position of the furnace, the axis of the shell, methods of circulation of water, and steam, and the use.