Industrial Boiler Manufacturers in India

We at SILSON are one of the leading Industrial Boiler Manufacturers in India. Trusted Industrial Boiler Suppliers in India. Our expertise throughout several years combined with our dedication to premium products generates diverse industrial boiler systems suitable for numerous industries in India. Our production facilities include advanced manufacturing techniques that build boilers for excellent operational efficiency enduring reliability and economical operation.

Industrial Boiler Suppliers in India

Industrial Boilers are allowed to use modern high-quality materials to construct boilers that match international specifications. Our industrial boiler solutions adapt to meet any industrial need for power generation manufacturing facilities or other industrial spaces.

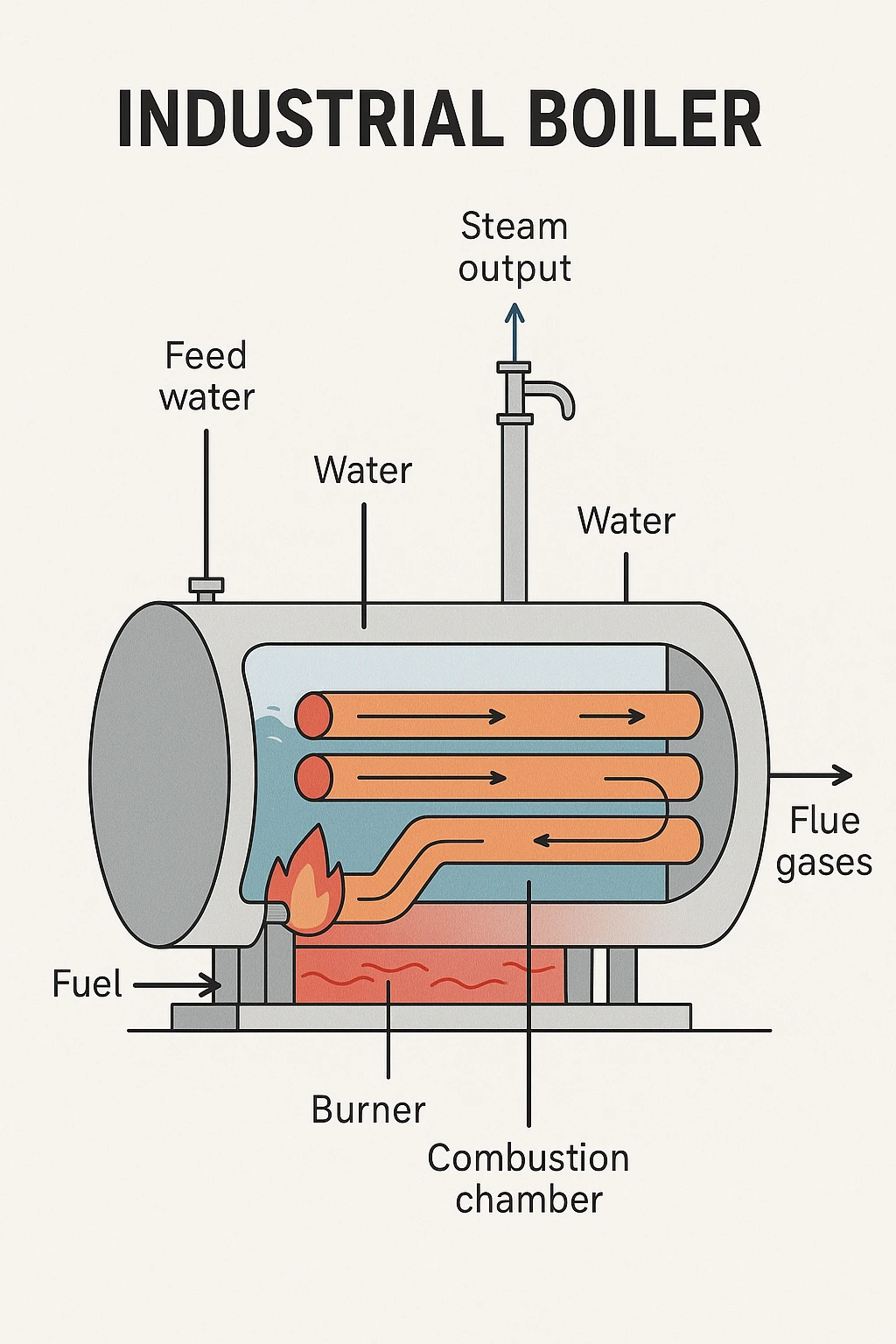

What is the Industrial Boilers

Tempering and producing steam or hot water at scale is the fundamental task of industrial boilers as industrial systems. The system utilizes fuel and electrical energy to reach high water temperatures before creating steam that drives turbines warms equipment and operates machines. The manufacturing needs of power generation, food production, and manufacturing depend heavily on boilers to operate their processes. We stand as a trusted Industrial Boiler Suppliers in India that combines timely delivery with exceptional customer service throughout India. We offer dependable boilers with unmatched performance levels that fulfill all industry requirements.

Types of Industrial Boilers

We are well known Industrial Boiler Manufacturers in India. That's why we have present an extensive range of high-grade boilers that are flexible enough to be applied in all types as follows:

- Industrial Steam Boilers: Industrial facilities use massive high-efficiency steam boilers to create steam which powers multiple production procedures including energy production and heat supply and industrial plant operations. Steam boilers receive fuel from natural gas oil and coal which generates heat for water to transform into pressurized steam.

- Water-tube Boilers: Circulation through tubes is the basis of these boilers, allowing external heater combustion gases to heat the water containers. The boilers excel at high-pressure functions because they operate efficiently.

- Firetube Boilers: The tubes in these boilers run parallel with hot gases flowing through an external water containment. Low to medium-pressure systems frequently use these boilers because they require less upkeep.

- Coal-fired Boilers: The operation of these boilers depends on burning coal material to obtain steam production. Such boilers serve power generation facilities and industrial complexes yet create greater environmental issues due to released carbon substances.

- Oil/Gas Boilers: Natural gas together with oil functions as fuel sources to heat water or generate steam inside these Oil/Gas Boilers. The technology functions well and finds installations in homes and factories across different locations.

Specifications of Industrial Boiler

We have added below a technical sheet of our Industrial Boiler that provides more technical information.

We have designed each model to help for better understanding of the specifications and performance capabilities of our Industrial boilers in India. Feel free to reach out if you need any clarification or assistance in choosing the right model for your needs. We’re here to support you with detailed insights and expert guidance every step of the way.:

| Specifications | Details |

|---|---|

| Capacity | 500 kg/hr to 100,000 kg/hr |

| Operating Pressure | 10 to 100 bar |

| Fuel Type | Natural Gas, Diesel, Coal, Biomass, Oil, etc. |

| Efficiency | 80% to 95% |

| Combustion Chamber | Fully welded, cast iron, or refractory lined |

| Water Treatment System | Deaerator, softeners, or reverse osmosis systems (optional) |

| Material of Construction | Carbon Steel, Stainless Steel, Alloy Steel, or Composite Materials |

| Burner Type | Low NOx Burners, High-Efficiency Burners, etc. |

| Stack Design | Vertical, Horizontal, or Condensing Stack |

| Boiler Drum | Horizontal or Vertical, with or without steam separation devices |

| Boiler Efficiency Monitoring | Online efficiency monitors, Oxygen & CO₂ measurement |

| Boiler Water Volume | Typically 50–5000 m³ |

Benefits of Industrial Boiler

Being one of the Renowned in the category of Industrial Boiler Suppliers in India, all types of boilers are made using advanced technology and hence offer a variety of benefits such as:

- Efficient Energy Utilization: High-rate fuel-to-heat conversion in these boilers generates maximum energy efficiency that cuts operational expenses and minimizes energy waste. The boosted efficiency of production processes becomes possible because of this method.

- Cost-Effective Heating: The use of boilers as a heating system enables industrial facilities to maintain cost-efficient operations while maintaining steady temperatures across production areas which leads to diminished energy costs.

- Environmental Sustainability: Modern boilers incorporate technological innovations that lower pollution emissions through their use of sustainable energy sources and conservation elements.

- Enhanced Productivity: The continuous operation of industrial boilers leads to improved manufacturing efficiency and factory productivity rates keep increasing.

- Versatility in Fuel Options: The industrial boiler system offers flexibility regarding fuel selection since it operates on natural gas and coal as well as biomass together with oil according to business needs.

Applications of Industrial Boiler

As Reliable Industrial Boiler Manufacturers in India, our boilers are highly demanded for multiple types of applications and used for improving performance, such as:

- Power Generation: These boilers power electricity production in power plants through the process of transforming fuel thermal energy into steam. The generated steam operates turbines which then power generators to produce electrical energy.

- Heating Systems in Industries: The textile and pharmaceutical industries together with food processing rely upon boilers to produce steam for their heating operations. The production lines depend on boilers to keep their temperature levels stable for maintain product quality while excelling in operations.

- Chemical Processing: Boilers create steam within the chemical industry which enables heating of reactors and distillation columns between other chemical processes. The required heat ensures proper conditions for multiple chemical reactions to occur.

- Food and Beverage Processing: Boiler heat serves multiple purposes in food production as it enables cooking and sterilization along with pasteurization of beverage and food items. Temperature management through steam enables safe sterilization and successful canning as well as drying operations to protect food quality.

- Pulp and Paper Industry: The pulp manufacturing process requires steam produced by boilers and these boilers also enable drying operations while generating mill power. Wood chips undergo breakdown using steam while steam powers machinery necessary for paper production.

We are the most trusted Industrial Boiler manufacturers in India and Premium Industrial Boiler suppliers in India at SILSON, deliver quality innovative solutions while maintaining absolute customer satisfaction. We create reliable solutions economically designed to serve various industries through our diverse product range. Organizations view us as a dependable alliance due to our qualifications in complex boiler design and maintenance work. Contact us immediately for top-grade industrial boiler solutions.

People also searched: Top 10 Boiler Manufacturers In India, औद्योगिक बॉयलर भारत, Boiler Manufacturer, Best Boiler Manufacturer in North India, Boilers - Product Range, Steam Boilers Manufacturers in India, स्टीम बॉयलर इंडिया, Trusted Industrial Steam Boiler Manufacturer, Boiler Manufacturer in India, List of industrial boiler manufacturers in india, Top industrial boiler manufacturers in india, Top 10 industrial boiler manufacturers in india, Top 20 boiler manufacturers in India, Top 20 industrial boiler manufacturers in india, Steam boiler manufacturers in Pune, List of boiler manufacturers in India, Boiler Manufacturer- Industrial Steam Boiler Manufacturer, Biggest 10 Boiler Manufacturing Companies in India 2022, India's No.1 Steam Boiler Manufacturer & Supplier, Top 10 Steam Boiler Manufacturers in the World, IBR Steam Boiler Manufacturer from Ahmedabad, Top Industrial Boiler Manufacturers in Chennai near me, Top industrial boiler suppliers in india, Top 10 industrial boiler suppliers in india, List of industrial boiler suppliers in india, Best industrial boiler suppliers in india, Industrial boiler suppliers in india contact number,

FAQ

Ans: Industrial boilers are used to produce steam or heat water for space and process heating and for the generation of mechanical power and electricity.

Ans: Two main boiler technologies are currently available in the market: watertube and firetube boilers.

Ans: Although other fluids are sometimes used for these purposes, water is by far the most common. Boilers find application in key industries sectors of oil & gas, power, steel, fertilizers, chemicals, cement etc.