Industrial Boiler Manufacturers in Pune

SILSON Boilers is leading Industrial Boiler manufacturers and suppliers in Pune, we have completed in excess of 300 projects in India and completed in excess of 75 projects abroad with a proven track record of over 30+ years. Supported by an 110+ team of solid expert engineers - is dependable. Silson is a certified company that conducts its operations according to ISO 9001:2015 and possesses the most reputable IBR (Indian Boiler Regulations) certification. The Directorate of Steam Boilers has qualified us as a Class 2 Boiler Manufacturer and has allowed us to produce shell and composite boilers with a maximum pressure of 40 kg/cm2. We have a diversity of certifications including the Pipeline Fabricator, Pressure Part Manufacturer as well as Pressure Vessel Manufacturer certifications; therefore, all our products are of high-quality criteria both nationally and internationally.

What is Industrial Boiler?

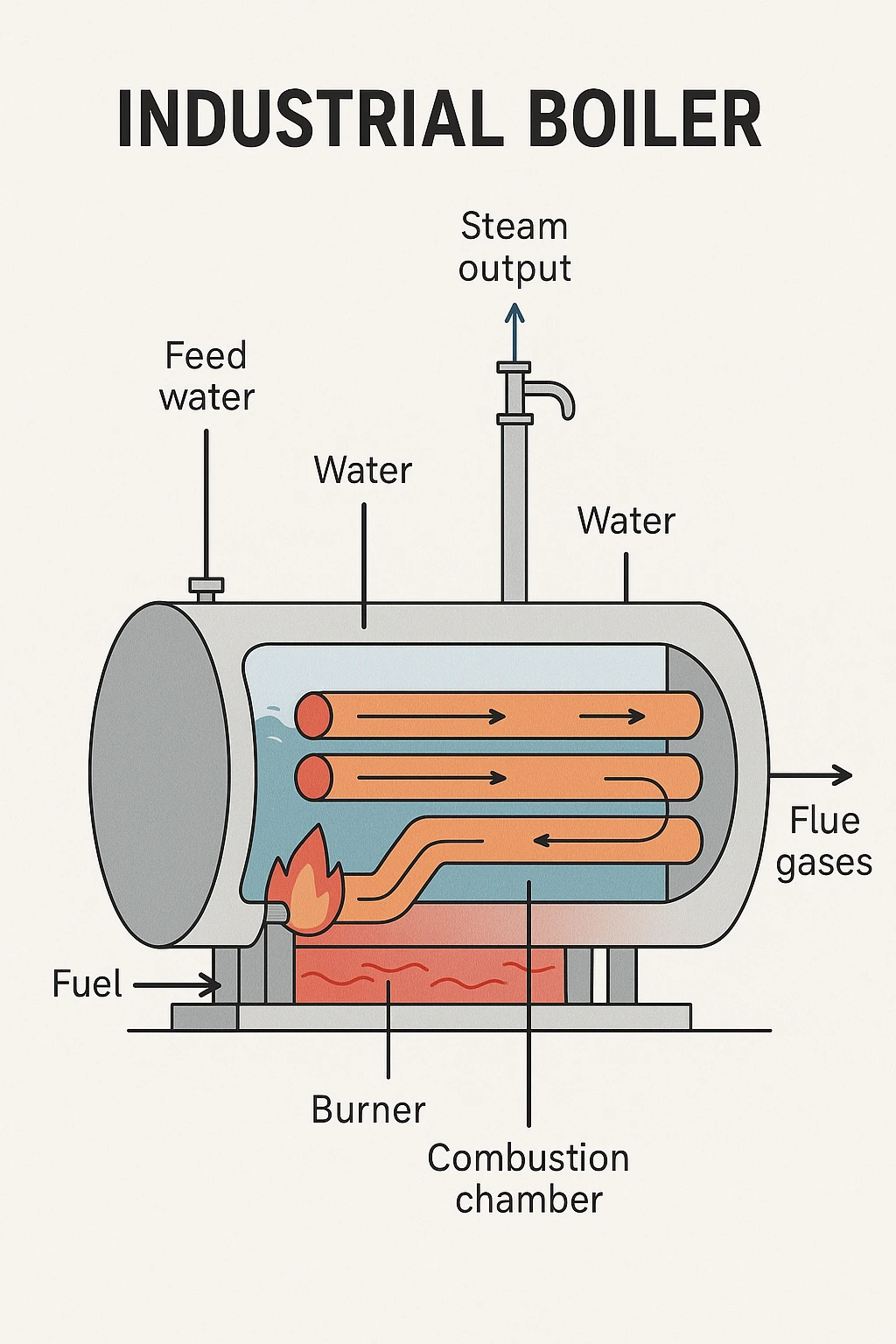

An industrial boiler is a closed container that is used to heat either water or produce steam under pressure using a source of fuel. This hot water or steam is then pumped via piping system to give energy to other ways of heating and processing in industries. We as Industrial Boiler manufacturers in Pune are a business establishment that aims at becoming a full-service provider of process industries. We are also involved in production and distribution of Industrial Boilers such as Solid Fuel, Oil/Gas Fired and Membrane. With technical knowledge and a trail of creative engineering, we are able to offer turnkey solutions- starting with the initial design and fabrication stage to delivery and after sales services- in order to assure ultimate efficiency and reliability to our clients worldwide.

Types of Industrial Boiler

Being as Industrial Boiler manufacturers in Pune, we provided different types according to operations which are given below.

- Solid Fuel Fired Boilers: This is a very efficient type of system that is designed to produce steam through the use of biomass, coal or agro-waste fuels.

- Oil & Gas Fired Boilers: These are heating systems that are dependable, low-emission, and highly efficient, which are easily automated with liquid or gas fuels.

- Twin Furnace Boilers: Large capacity boilers with two firing systems to offer improved steam production to large industries for Industrial Boiler suppliers in Pune.

- Coal-fired Boilers: These boilers are used in power generation plants and industrial complexes but pose more problems to the environment through the emissions of carbon substances.

- Industrial Steam Boilers: Massive steam boilers with high efficiencies are used in industrial facilities to generate steam that is used in various production processes such as energy production, provision of heat and industrial plant operations.

- Water-tube Boilers: These boilers are founded on the idea of circulation via the tubes, and the external heater combustion gases can be used to heat the water containers. The boilers are good in high-pressure operations since they are efficient.

- Firetube Boilers: The tubes in this type of boiler run parallel with hot gases passing through external water tank. These boilers are common in low to medium-pressure systems as they need less maintenance.

- Package Type Boilers: Shell-type boilers that are easy to assemble in factories, and safely operate manually by small- to medium-size industries.

Technical Specifications of Industrial Boiler

We've added below a specialized table of Industrial Boiler in Pune that provides further technical specification information.

| Specifications | Details |

|---|---|

| Capacity | 500 kg/hr to 100,000 kg/hr |

| Operating Pressure | 10 to 100 bar |

| Fuel Type | Natural Gas, Diesel, Coal, Biomass, Oil, etc. |

| Efficiency | 80% to 95% |

| Combustion Chamber | Fully welded, cast iron, or refractory lined |

| Water Treatment System | Deaerator, softeners, or reverse osmosis systems (optional) |

| Material of Construction | Carbon Steel, Stainless Steel, Alloy Steel, or Composite Materials |

| Burner Type | Low NOx Burners, High-Efficiency Burners, etc. |

| Stack Design | Vertical, Horizontal, or Condensing Stack |

| Boiler Drum | Horizontal or Vertical, with or without steam separation devices |

| Boiler Efficiency Monitoring | Online efficiency monitors, Oxygen & CO₂ measurement |

| Boiler Water Volume | Typically 50–5000 m³ |

Benefits of Industrial Boiler

We as Industrial Boiler suppliers in Pune, according to conditions we provided different benefits which are given below.

- High Thermal Efficiency: We have developed boilers that have multi-pass system to achieve high heat transfer and reduced fuel wastage. Industrial Boiler manufacturers in Pune would save a lot of costs in energy consumption within long term process in industry.

- Operational Reliability: These boilers have been designed using strong material and IBR-approved parts which provide high reliability in high-pressure conditions.

- Multi-Fuel Flexibility: We have designed several of our systems to operate with different fuels such as coal, wood, agro-waste, oil, or gas. This enables industries to alternate fuels depending on the availability and cost-effectiveness without equipments.

- Improved Safety: Our boilers have the highest standards of safety: they have an improved safety valve, water level controller, and pressure switch that reduces the risk of accidents. The ISO and IBR standards are followed strictly, and this can be considered a guarantee of safe working environment of the plant operators.

- Low Maintenance Design: With doors that are easy to access and end to end tube view, our boilers make the cleaning and inspection process simpler.

Applications of Industrial Boiler

We serve as Industrial Boiler manufacturers in Pune; it is applicable in different industries which are given below.

- Food and Beverage Processing: Boilers are used to supply the required steam to cause sterilization, pasteurization and cooking in the large-scale food plants. They guarantee food safety and quality by ensuring that they have sort of accurate temperature controls when they make them.

- Pharmaceutical Manufacturing: In this industry, dry steam is featured to produce high quality, which is utilized to sterilize equipment and produce chemical reactions. Our boilers assist in keeping the high hygienic standards demanded in production of medicines.

- Chemical and Fertilizer Plants: A major source of heat in the distillation of different chemical compounds, evaporation, and heating of different chemical compounds is through boilers. They play critical roles in the transformations of complex chemistry in large scale reactors.

- Textile Industry: Steam is widely applicable in the process of dyeing, drying, and finishing fabrics so as to obtain the required texture and color. We supply high-volume steam required to drive continuous textile processing lines using our boilers.

- Paper and Packaging: The production of paper involves huge volumes of heat in pulping and drying paper sheets on huge rollers. Industrial boilers maintain constant supply of heat to bring these energy consuming machines into full operation in Industrial Boiler suppliers in Pune.

Why choose us as Industrial Boiler in India

- Years of Experience: More than 30+ years of industry experience in the field of steam engineering and boiler construction.

- Certified Quality: Certified products by IBR approved and ISO 9001:2015 certified products that guarantee global safety standards.

- Experience: Positive completion of 300+ domestic and 75+ international projects.

- Tailor Made Engineering: Capacity to design and produce boilers according to special needs in terms of pressure and capacity.

- In-House Facility: On-site manufacturing and test department.

- Regulatory Compliance: Strict Indian Boiler Regulations (IBR) Compliance.

SILSON is prominent Industrial Boiler manufacturers and suppliers in Pune, Our Boilers provides high-performance steam solutions to revolutionize the productivity of your plant, the leader trusted by India! We are the pioneering masters of the engineering field with the 35+ years of mastery in IBR-certified boilers and we are delivering the incredible fuel efficiency, as well as the rock-solid reliability of the boilers. It could be solid fuel, oil or gas-fired system, but whatever the case is we have designed innovative designs that will drive your growth through a reduction in operational expenses. Select the partner, which 300 plus global industries can rely on precision and safety. The Silson experience is one that combines the latest technology with the very best craftsmanship! Contact us as more details.

FAQs

Ans: Our boilers are multi-purpose and can be configured to operate on either solid-fuel such as coal, wood, and agro-waste, or liquid/gaseous fuels such as LDO, HSD, and Natural Gas.

Ans: IBR (Indian Boiler Regulations) certification is a guarantee that the boiler is constructed, built and tested in compliance with stringent safety requirements in order to avoid explosions and meet legal requirements within India.

Ans: Yes, Silson can offer full turnkey solutions in which they design and produce a product and then install and commission it at the location.